Design

After Studying the requirement of customer and partnering with a specialized Data Center designer we always take the following and consideration.

- Design to be as simple as possible

- Design to be upgradeable

- Design to be flexible

- Label everything – Particularly cabling

- Taking under consideration “customer growth for 5 to 10 years

Power Architecture

By understanding the main requirement of our customers Data Center to always make sure that all main Panel Board are labeled and installed

- Main Distribution Panel Board

- A/C Distribution Panel Board

- UPS Distribution Panel Board

- Power Distribution Outlets

- Electrical Cables

- Grounding System

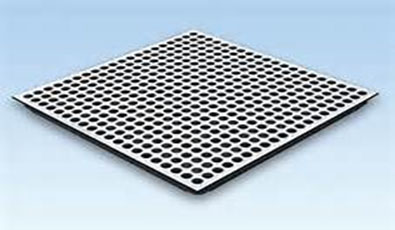

Raised Floor

- High density chipboard panels that can be lifted

- Adjustable construction height

- Easy access to below area; Power & Network Cables resting on cable trays

- Wooden Ramp with Anti Skid Rubber Tiles for easy access

- Perforated panels for A/C ventilation

- Concentrated Load : 5KN (500Kg)

Structured Cabling

Using customer layout for their location we always consider the following:

- Cabling System for easy maintenance and space optimization

- Horizontal & Vertical cabling

- Separate cable for Data & Power using Cable tray, Ladder system, Basket system, Fiber Runner and Bus-way system

- Advanced testing machines & reporting

- Labeling for ease of management

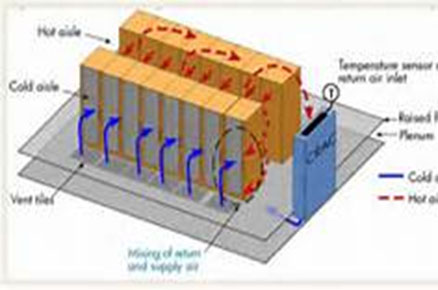

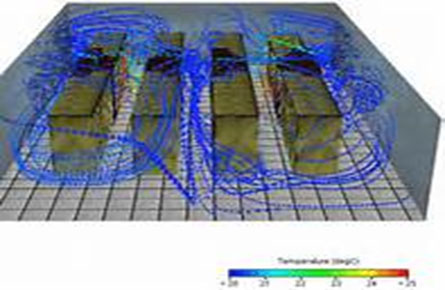

Cooling System

- Precision Cooling Up-Flow & Down-Flow Full Function with redundancy

- Complete with pre-heaters, humidifier and microprocessor

- Cooling Capacity of 5, 7 or 10 Tons sufficient for different DC’s & very huge Capacity (Up to 200 Tons) for different locations

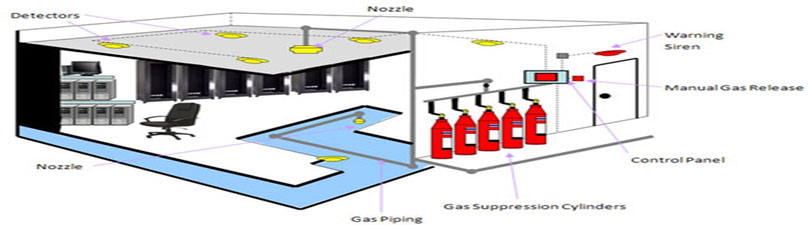

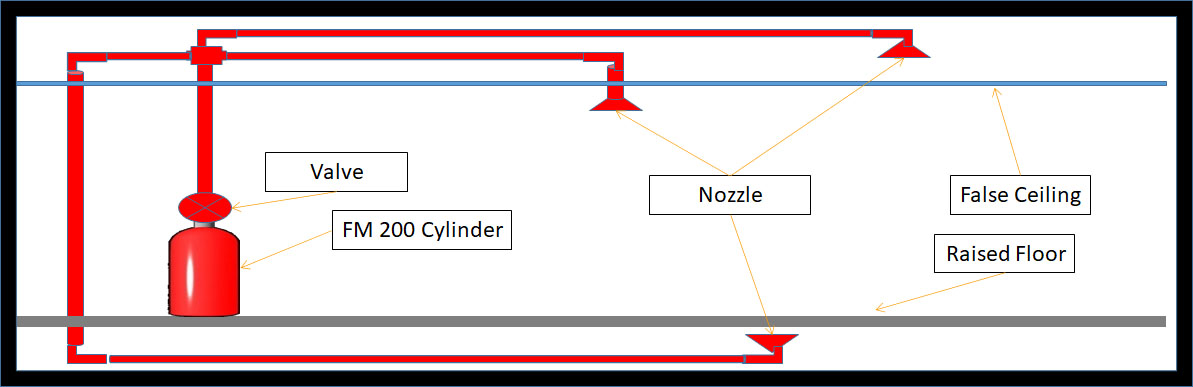

Fire Alarm & Fire Suppression System

Uninterrupted Power Supplies (UPS)

- UPS must have built-in N+1 redundancy

- Remote Monitoring of UPS

- Automatic bypass if component fails

- Communication Cards

- Parallel Configurations

Standby Diesel Generators

Based on the requirement of our customer Generators cab be supplied with different size and capacity. Service of generators should include the following :

- Civil work & Connectivity

- Static Battery Charger

- Circuit Breaker

- Soundproof enclosure (If requested)

- Electric Pump with Control Panel

- Main tank for Fuel / Subbase Tank

- Concrete Foundation for Generator

- Security Fence